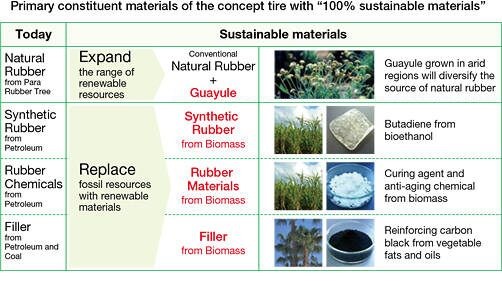

Merely reducing raw material consumption (Action 1) and using recycled resources (Action 2) will not be enough to ensure a reliable supply of products and services needed to meet the continuously increasing global demand. By further expanding and diversifying the renewable resources it uses to make its products (Action 3), Bridgestone can help build a truly sustainable society.

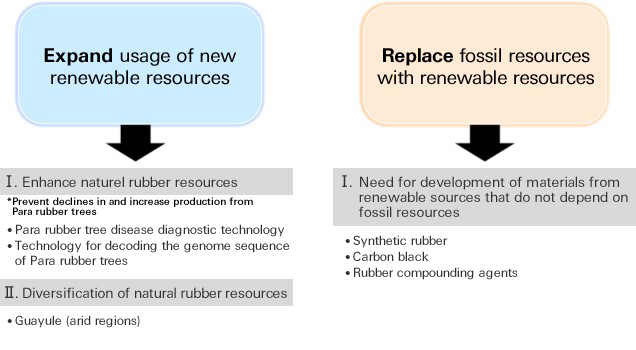

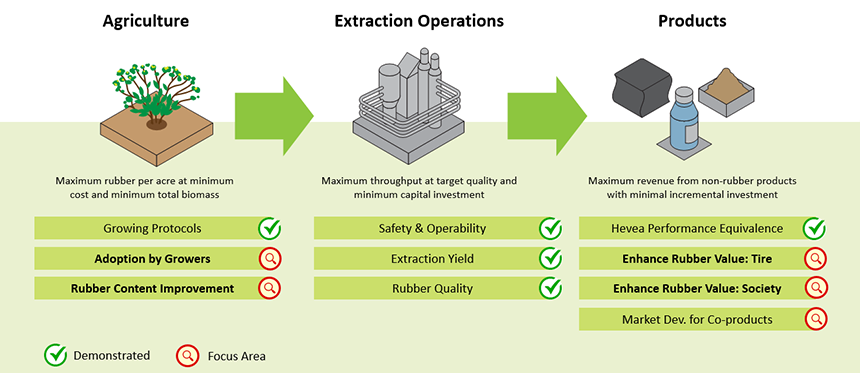

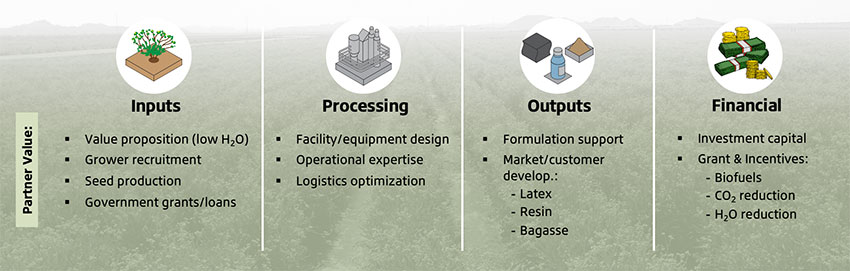

The approach to using sustainable materials focuses on balancing resource use with the Earth's capacity. It is acknowledged that switching from non-renewable materials to plant-derived renewable resources alone is insufficient. For instance, Bridgestone is working to diversify its renewable material sources by developing guayule and other alternatives for natural rubber. Additionally, efforts are being made to increase the productivity of cultivated rubber trees, which are currently the main source of natural rubber for tires.

By helping boost the productivity of small farms (see the “Enhancing contribution” section for details), as well as by both improving productivity and diversifying its current supply sources through innovative technological development, Bridgestone is working to ensure the future sustainability of its sources.