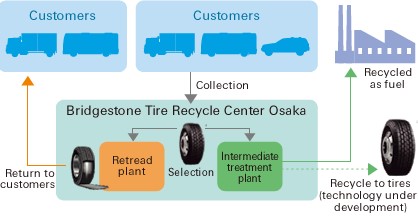

Bridgestone is working to improve product circularity.*1 This involves utilizing or disposing of used tires*2 collected at stores while complying with the laws and regulations of each country and region. In 2024, 99% of Bridgestone's 3,400 equity stores worldwide have a contract with a processing company with beneficial next-use stipulation. Bridgestone is working to create new value through tire recycling, including the effective use of collected used tires.

Bridgestone specifically promotes the following activities globally:

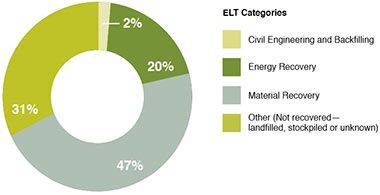

- Effective beneficial next use of used tires collected at stores (material recycling, energy recovery)

- Participation in regional and global initiatives

- Collection of discarded tires to clean up the environment in collaboration with NGOs

Examples include initiatives where used passenger car tires and truck and bus radial tires (TBRs) are beneficially recycled and recovered, and then used as construction materials, landscaping mulch, floor mats, and crafts.