Construction of a pilot demonstration plant for precise pyrolysis of end-of-life tires

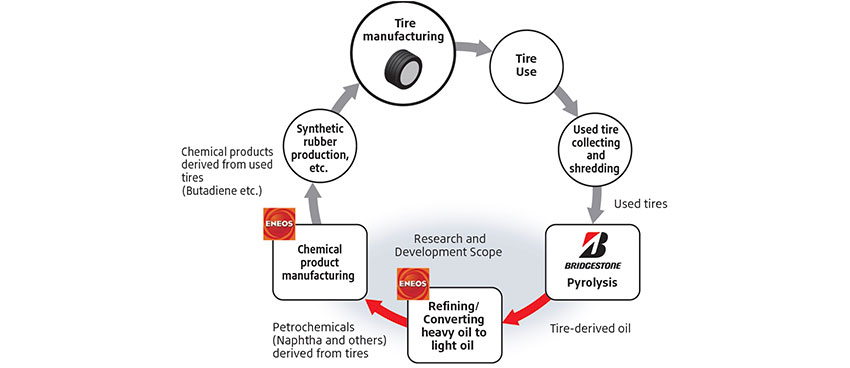

Bridgestone plans to construct a pilot demonstration plant for precise pyrolysis of end-of-life tires at its plant in Seki City, Gifu Prefecture, in Japan. The plant will start operating in 2027 with an aim to realize the horizontal recycling of tires. The facility will demonstrate the technology needed for establishing and optimizing precise pyrolysis of end-of-life tires, which involves obtaining tire-derived oil and recovered carbon black from the tires. In demonstrating this technology, Bridgestone aims to help accelerate the social implementation of chemical recycling technology.

This pilot demonstration plant implements the foundational technology for precise pyrolysis obtained from the demonstration machine introduced at Bridgestone Innovation Park (BIP) in Kodaira, Tokyo, in 2023. It aims to acquire knowledge on process design and quality control necessary for stable continuous operation and to establish scale-up technology for mass production of pyrolysis oil and recovered carbon black. Additionally, alongside technological development efforts, the plant will promote the construction of operational know-how and the development of human resources to support the realization of chemical recycling.

Chemical recycling technologies for high-yield production of isoprene by decomposing used tires at low temperatures

To highlight a related development, Bridgestone is collaborating on a project with the National Institute of Advanced Industrial Science and Technology (AIST) and Tohoku University, with partners ENEOS and JGC HOLDINGS CORPORATION, to co-create chemical recycling technologies for the high-yield production of isoprene, a raw material used in the production of synthetic rubber, by decomposing used tires at low temperature*1. By combining the expertise and technologies of industry-leading companies and academic institutions, Bridgestone is working to develop innovative recycling technologies that will contribute to the realization of a more sustainable society and to conduct demonstrations for the social implementation of these technologies by 2035.

These two projects, chemical recycling technologies that enable precise pyrolysis of used tires and chemical recycling technologies for high-yield production of isoprene by decomposing used tires at low temperature, have been adopted by the New Energy and Industrial Technology Development Organization (NEDO) of Japan as part of its Green Innovation Fund Project*2: Development of Technology for Producing Raw Materials for Plastics Using CO2 and Other Sources, with a project scale of 33.74 billion JPY and 23.03 billion JPY in funding. This funding will support their ongoing research, demonstration testing, joint research, etc.

- Rubbers and plastics are polymers created by linking monomers, such as isoprene and butadiene. Bridgestone is developing a process of decomposing used tires at low temperatures and then using a specialized catalyst to break them down into isoprene and other monomers (depolymerization).

- The Ministry of Economy, Trade and Industry (METI) of Japan established this program to help achieve the Japanese government's goal of carbon neutrality by 2050. It aims to accelerate structural transformation in the energy and industry sectors and innovation through ambitious investment. The fund continuously supports companies and other organizations that address challenges to move from R&D to demonstrations to social implementation of the outcomes within 10 years.