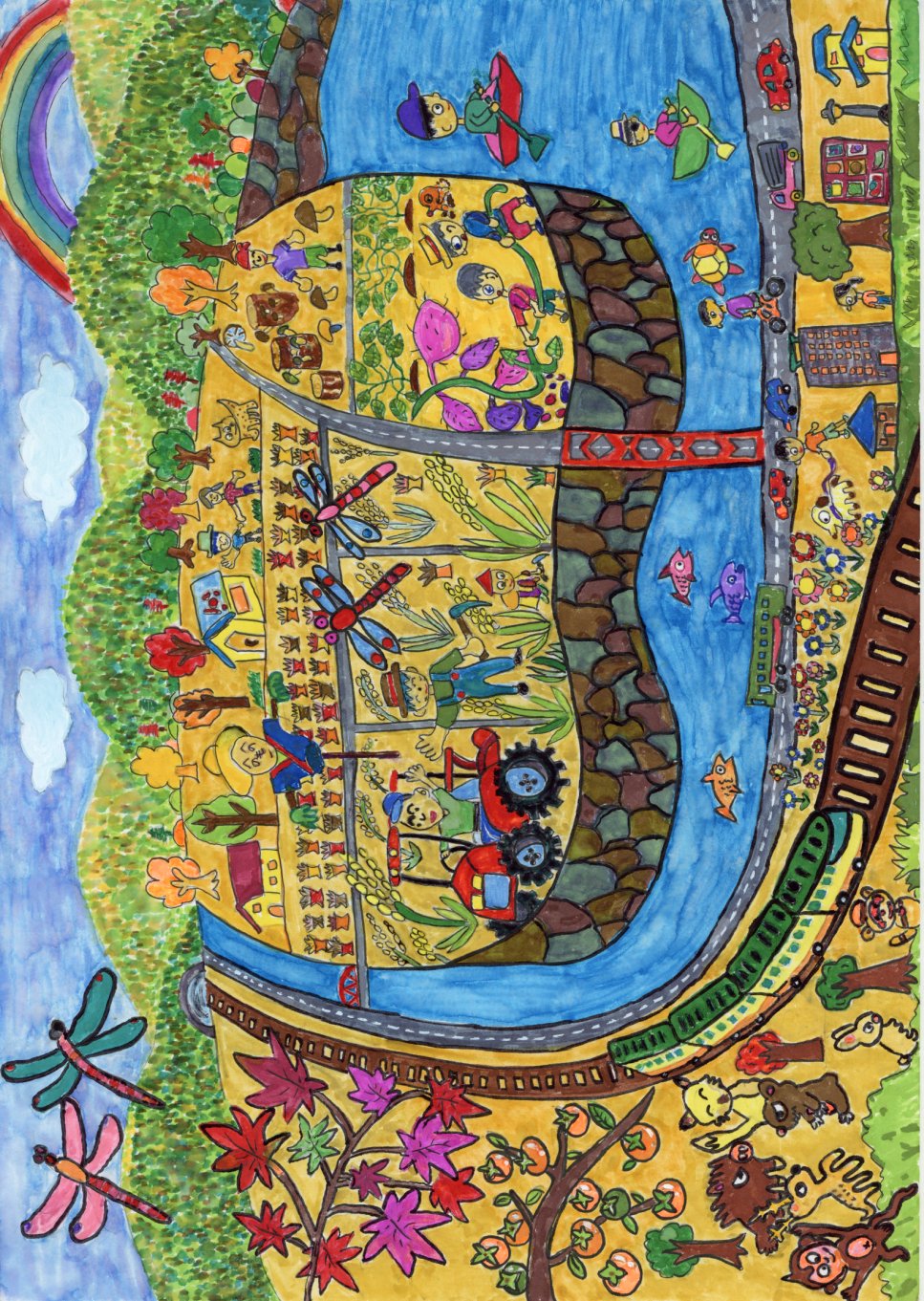

Para rubber trees are a major source of natural rubber, a critically important raw material for ensuring a sustainable supply chain for manufacturing tires. Natural rubber is a renewable resource that provides livelihood opportunities for millions of people around the world. The natural rubber economy is massive but fragmented, consisting of many complicated layers of raw materials dealers, processing plants, rubber product manufacturers, and smallholder farmers. Most of this rubber is grown by farmers in Southeast Asia, where rubber trees are planted on both small farms and large plantations. Globally, rubber tree farming provides employment for more than 6 million people.

Bridgestone uses large volumes of natural rubber, but unfortunately, many farmers face efficiency challenges and the natural rubber they produce varies in quantity and quality. To help smallholder farmers improve the quantity and quality of their farming operations, Bridgestone provides high-quality Hevea rubber tree seedlings and conducts technical training in key producing countries using the same productivity-improvement techniques it developed for its own rubber farms at the agricultural training center in the city of Siantar in North Sumatra. Bridgestone also implemented a technical training program for select instructor candidates.

Such initiatives are expected to improve the quality of natural rubber, increase income per unit area for the farmers, and help control expansion of agricultural lands.