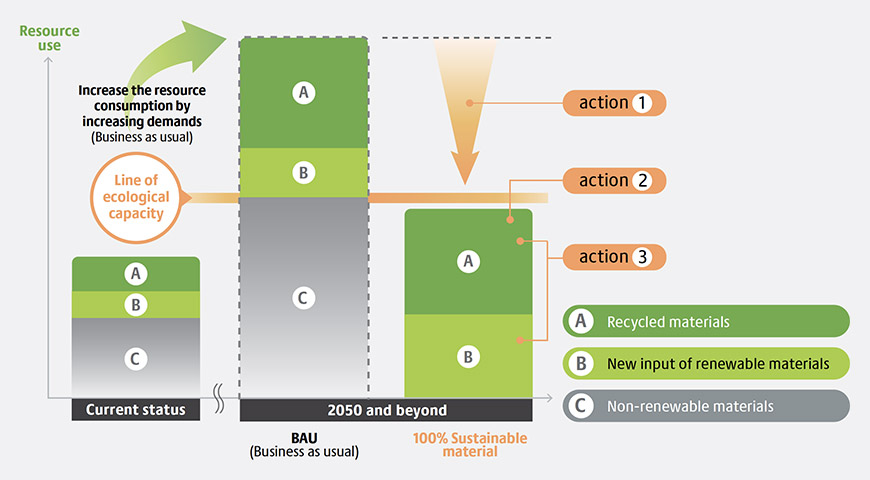

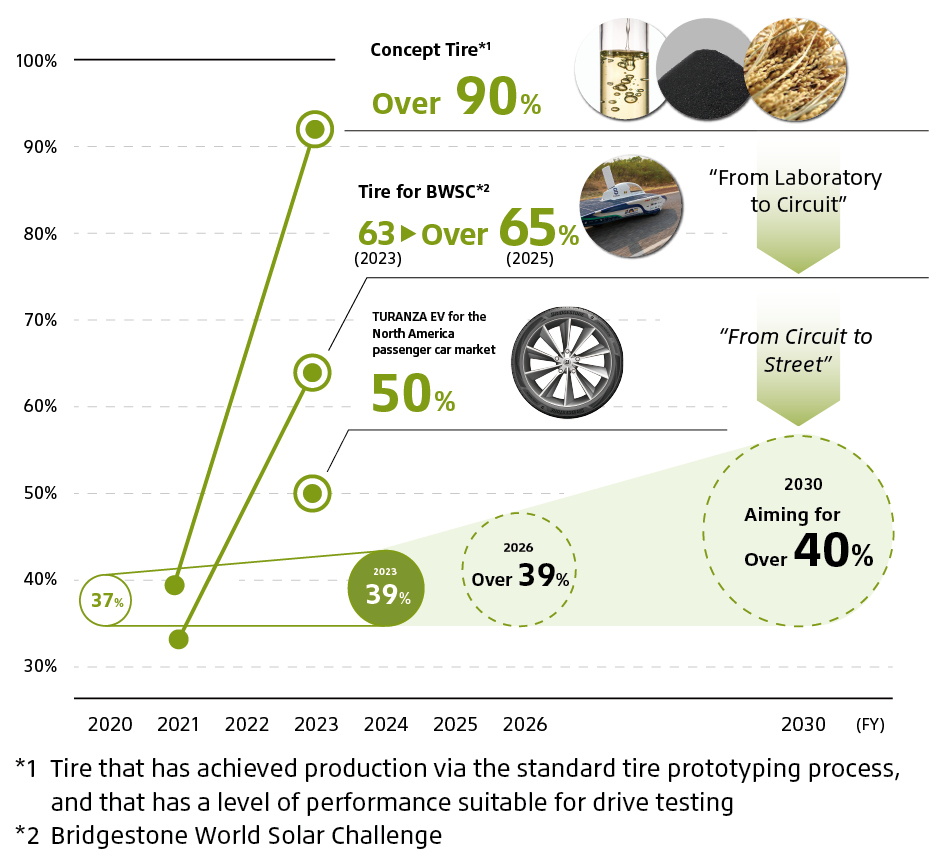

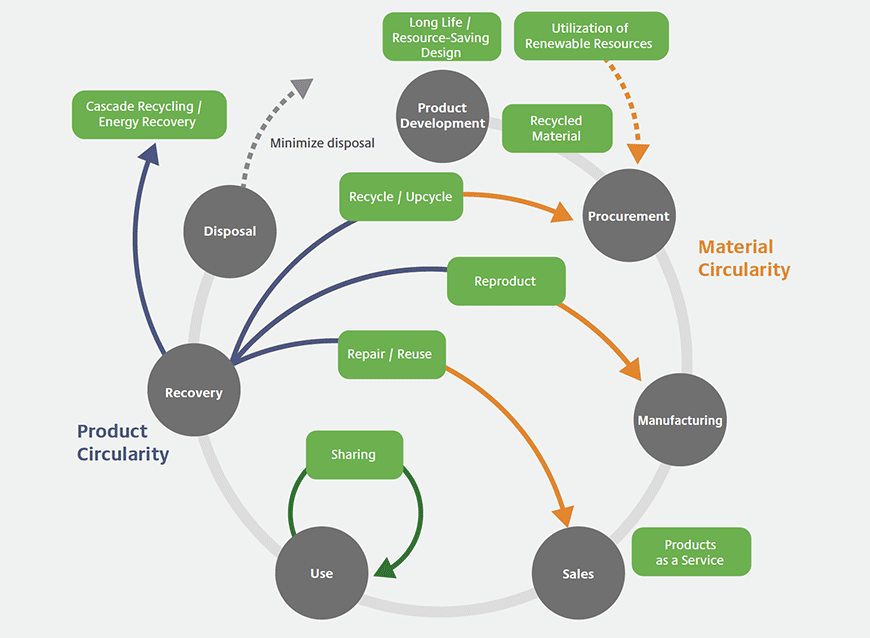

An increase in population and the number of automobiles will likely further boost tire demand in the future. The Bridgestone Group is working toward its goal to minimize resource depletion by implementing sustainable resource use through promoting technological innovation and business innovation. Bridgestone has set the goal of using “100% sustainable materials” in its products as the long-term environmental vision for 2050 and beyond.

Bridgestone defines sustainable materials as those that:

(1) come from resources with a continual supply;

(2) can be used as part of Bridgestone's business over the long term; and

(3) have a low environmental and social impact over their lifecycle from procurement to disposal.