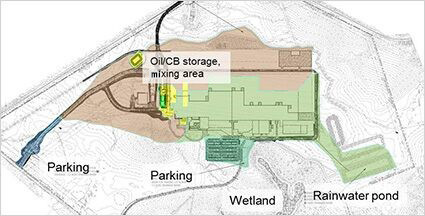

Bridgestone’s environmental mission is “to help ensure a healthy environment for current and future generations....” The environmental mission includes three focal points: existing in harmony with nature, valuing natural resources, and reducing CO2 emissions. “In harmony with nature” refers to biodiversity conservation and Bridgestone’s efforts to minimize the impact of operations on the overall ecosystem.

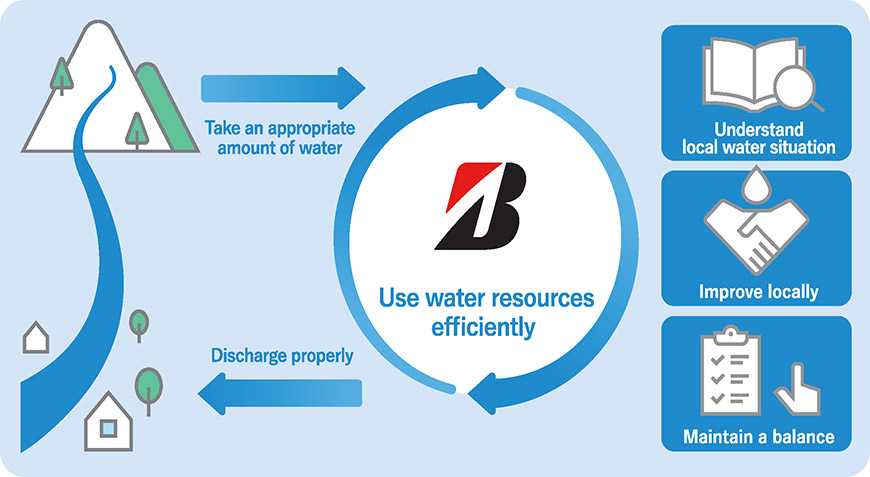

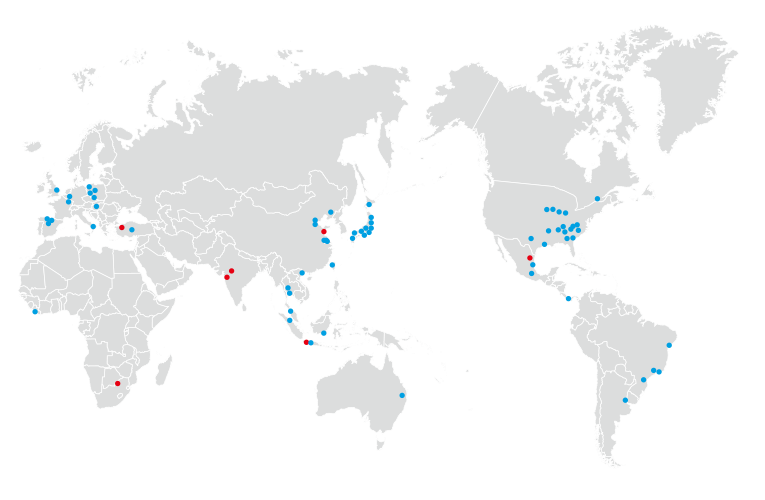

Bridgestone is engaged in various activities to help minimize the impact of its business activities on wildlife and natural habitats. It also engages in numerous activities to help improve the ecology within the production sites and the communities it calls home. These activities include reducing emissions, conserving water and other important natural resources, as well as implementing ecological improvements and education-related projects at business locations and in local communities.

Bridgestone intends to be even more ambitious in its activities in response to the continued importance of social and environmental issues and the potential impact that its business growth could have on the environment. To drive new achievements and further minimize its footprint, Bridgestone is building upon the various initiatives introduced in the previous mid-term target to reduce environmental impact on an ongoing basis.