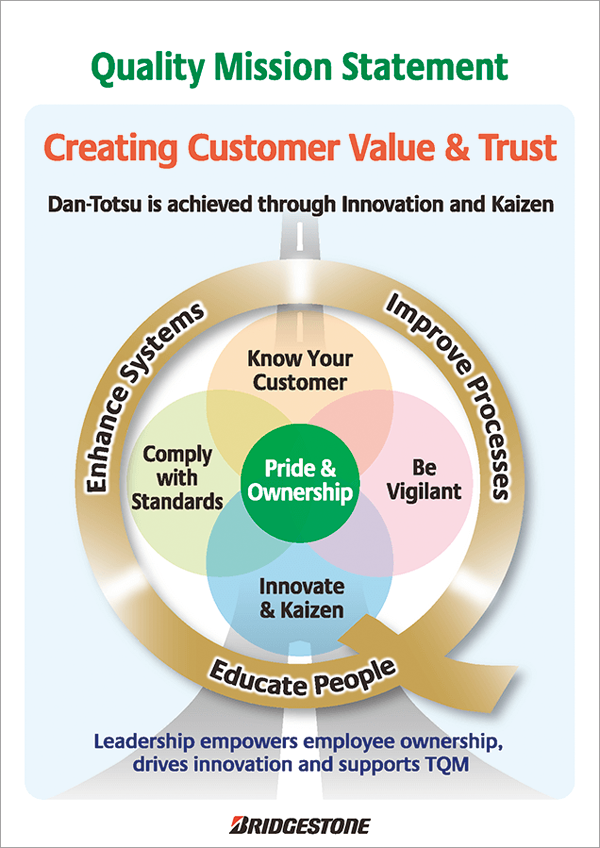

A commitment to quality is essential to achieving a sustainable society and providing people worldwide with safe and comfortable living through attractive, high-quality products, services and solutions. This commitment embodies the “Bridgestone E8 Commitment.” Bridgestone established its Quality Mission Statement to engage every employee in contributing to the creation of high-quality products, services and solutions that exceed customers' expectations through innovation and kaizen (continuous improvement).

The Quality Mission Statement is a blueprint for the future direction of Bridgestone and its leadership. It advances Bridgestone’s proud heritage of quality and commitment to continuous improvement, and is based on the spirit of its founder, Shojiro Ishibashi, who instilled these values in Bridgestone’s DNA.

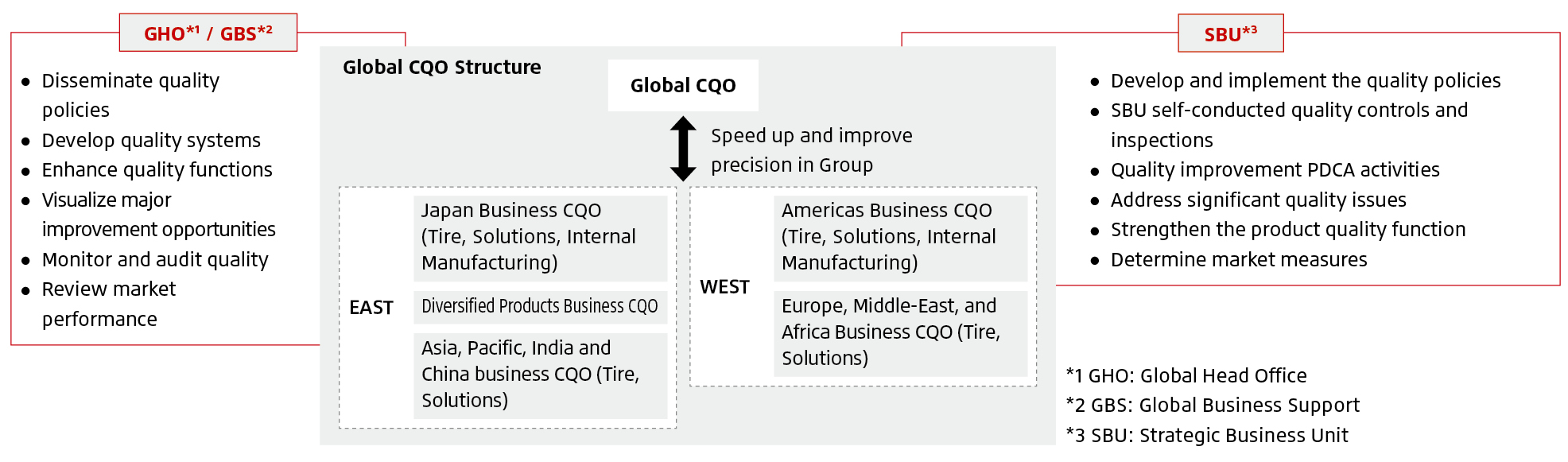

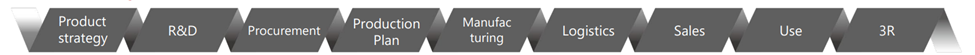

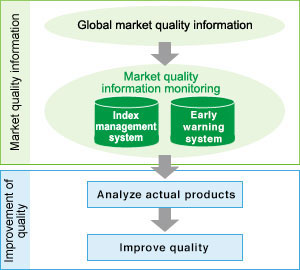

Through employee engagement with a commitment toward continuous improvement and innovation, Bridgestone strives to apply the principles of excellence to achieve superior quality throughout the entire value chain, globally across all businesses.

Bridgestone puts the safety of its customers and employees first and delivers products, services and solutions with superior quality.