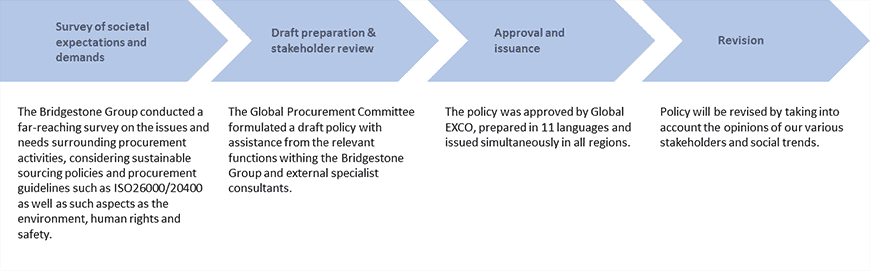

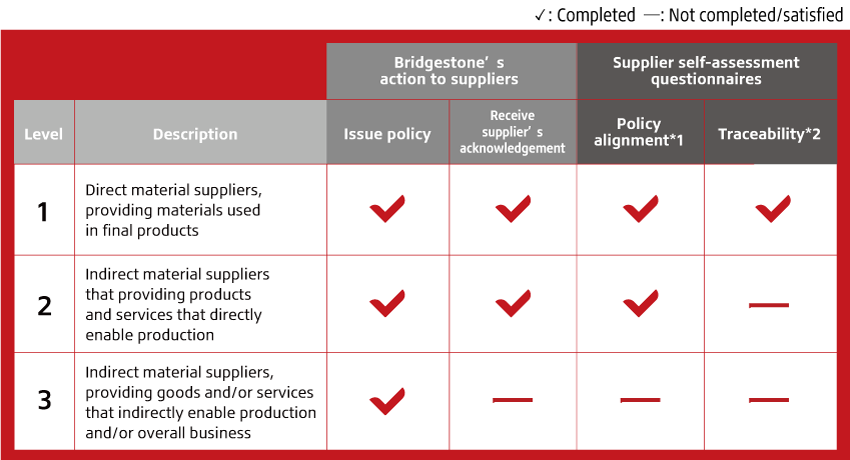

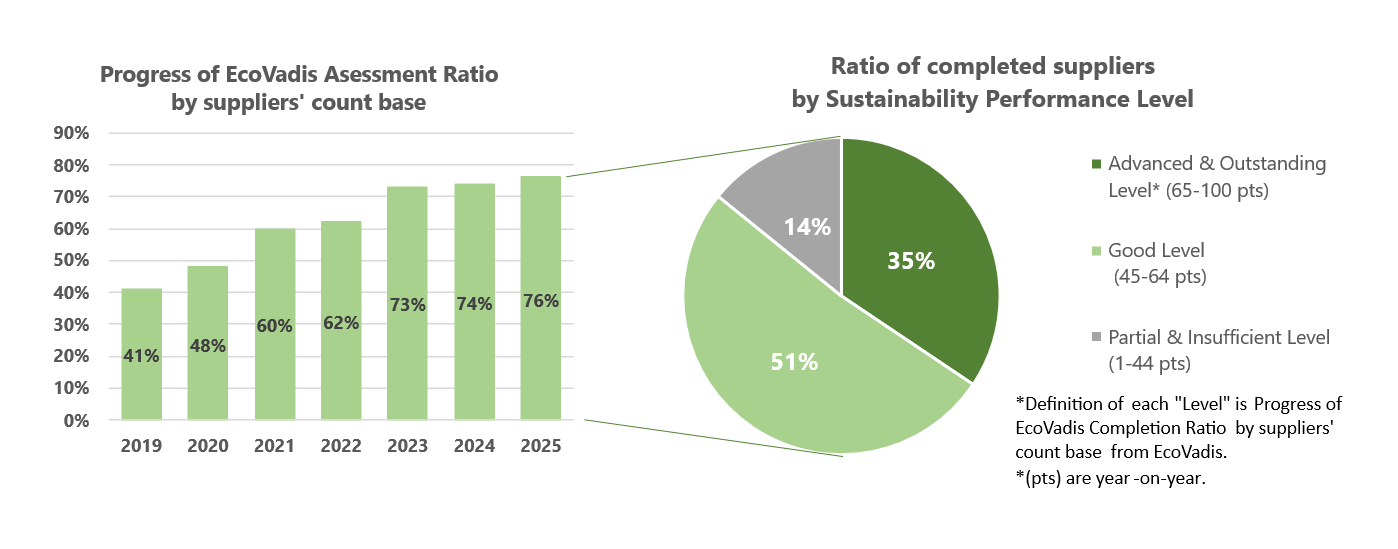

Bridgestone’s sustainable procurement initiatives create long-term environmental, social and economic benefits for stakeholders across its supply chain. This work is grounded in its Global Sustainable Procurement Policy and aligns with the Group’s goal of using 100% sustainable materials* by 2050 and beyond. The policy helps identify and evaluate qualified suppliers, promotes best practices, and serves as a communication and improvement tool for the industry.

Bridgestone’s sustainable procurement mission is important as customers and consumers are ever more interested in the natural rubber supply chain, including issues related to human rights and environmental practices of the rubber the Group sources. The policy was formulated paying close attention to international norms and fundamental principles for human rights reflected in a wide range of recognized commitments, including the United Nations (UN) Universal Declaration of Human Rights, the UN Guiding Principles on Business and Human Rights, and various International Labour Organization conventions, as well as ISO 26000 and 20400 standards on sustainable procurement and social responsibility.

Under this policy, Bridgestone has identified five key human rights issues for its business: child labor, forced labor, land rights, labor and working conditions, and fair and equal treatment. It has made a commitment to engage with stakeholders in identifying these issues in the future. Working with suppliers, the goal is to contribute to faster realization of a sustainable supply chain for the environment and communities around the world.

* Bridgestone defines sustainable materials as materials 1) that come from resources with a continual supply, 2) that can be used as part of its business over the long term, and 3) that have a low environmental and social impact over the lifecycle from procurement to disposal. For details on sustainable materials, see “Long-term environmental vision (2050 and beyond): Towards 100% sustainable materials.”