Double-Network Rubber Boasting Flexibility and Toughness for Realizing Both Fuel Efficiency and Durability

Contributions to Resource Conservation and Fuel Efficiency in Next-Generation Tires

Global warming and resource depletion are global issues that impact the environment and the sustainability of businesses across a wide range of industries. Specifically, this problem is contributing to a rising demand for resource conservation and increased fuel efficiency in automobiles. In response to this trend, initiatives for conserving resources and improving fuel efficiency and durability are advancing in the tire industry.

Double-network rubber is the result of an open innovation project advanced by Bridgestone, in collaboration with 12 research institutions. The project is aimed at developing an ultrathin and flexible polymer under the direction of Program Manager Kohzo Ito. Conducted through the Impulsing Paradigm Change through Disruptive Technologies Program (ImPACT) and spearheaded by the Cabinet Office’s Council for Science, Technology and Innovation, this project was designed to promote the rapid evolution of resource conservation and technologies for tires to contribute to a vehicle’s overall fuel efficiency.

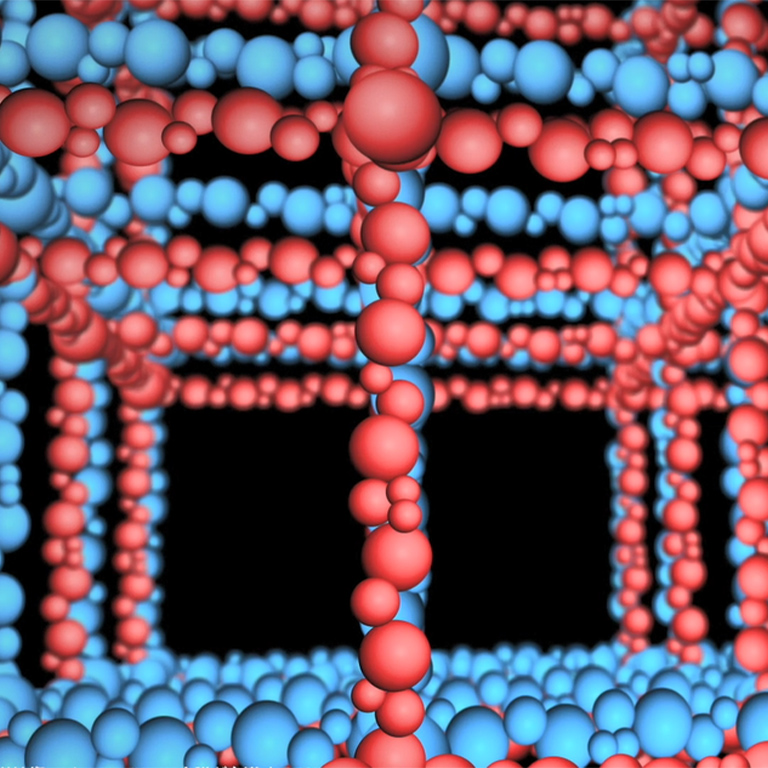

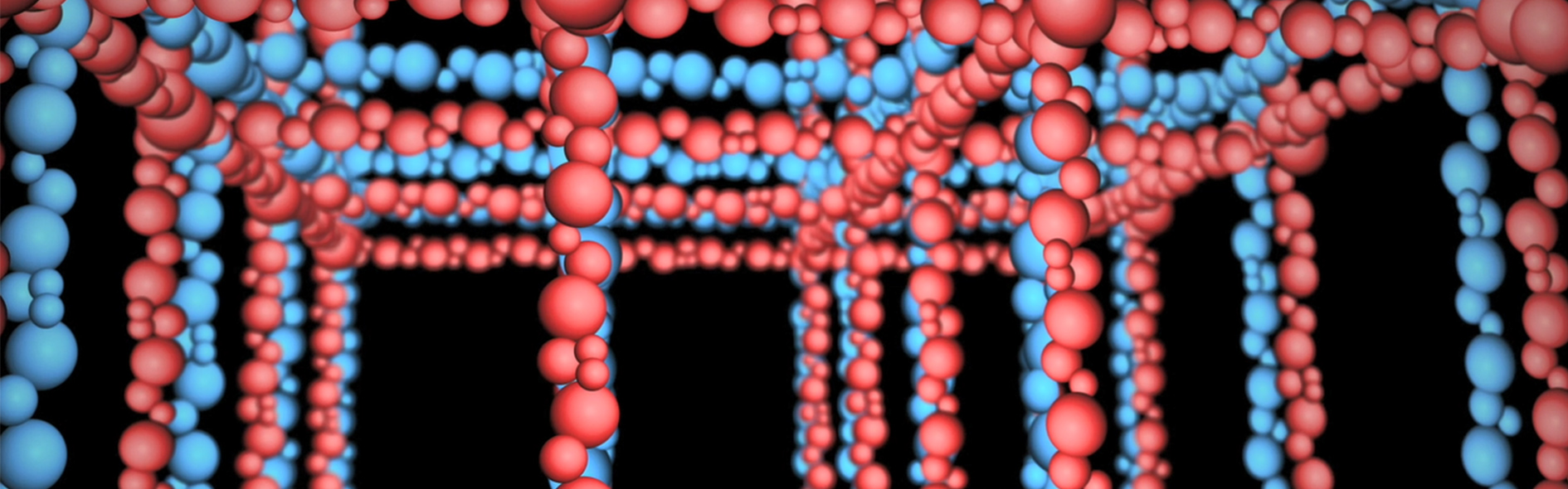

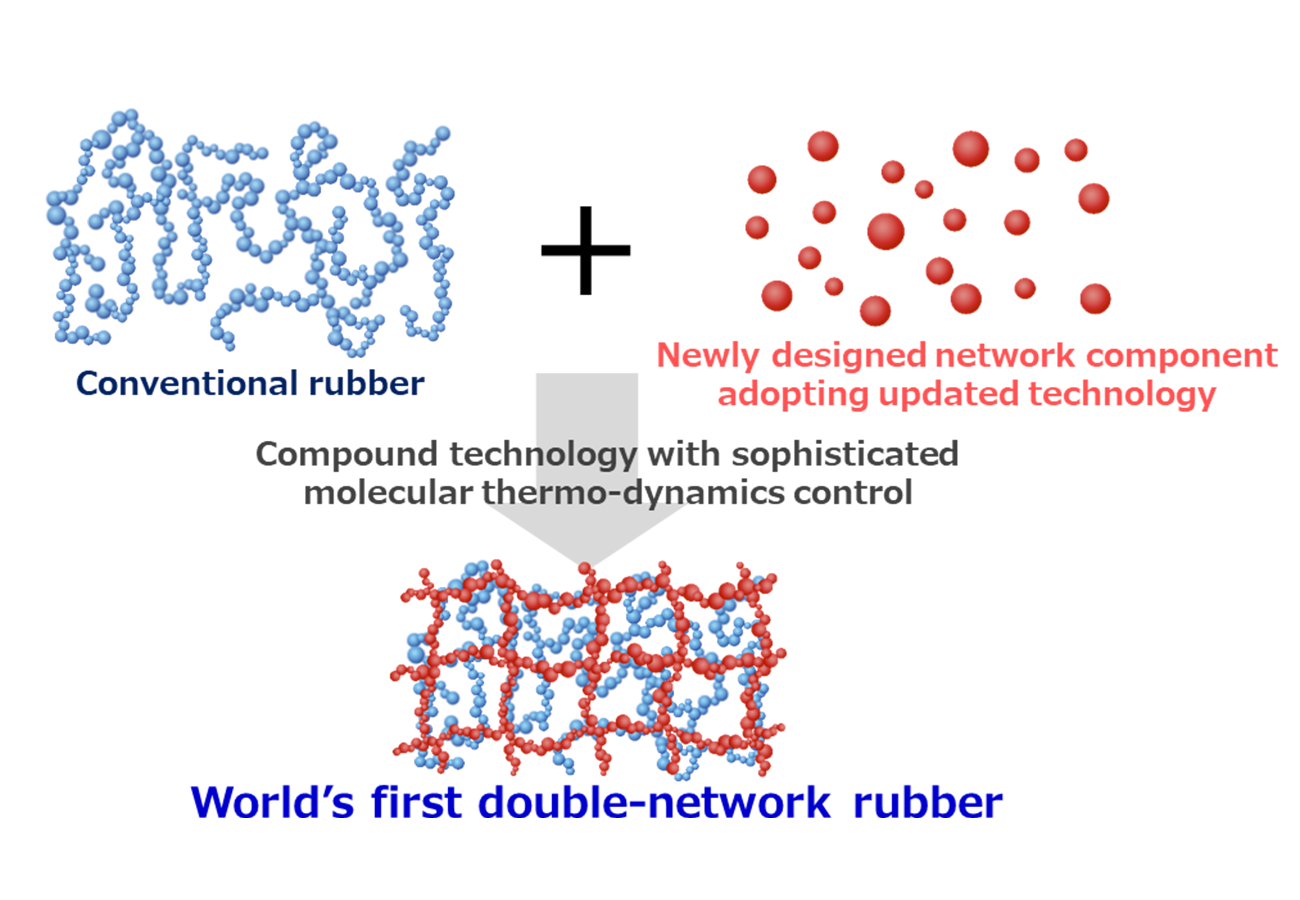

Structure of Double-Network Rubber

A double-network structure is designed to balance flexibility and durability. Achieving this balance is challenging, given the need to combine soft/flexible rubber and rigid/high energy dissipative rubber in the same structure. Previously, the effectiveness of double-network structures had been verified in gel materials. However, achieving a double network structure in a solid rubber compound requires sophisticated processing and compounding technologies, and therefore could not be adopted within the rubber industry.

The research project sought to develop specially designed network components and sophisticated molecular thermo-dynamics controlling process technology. The project succeeded in realizing a double network structure in rubber compounds.

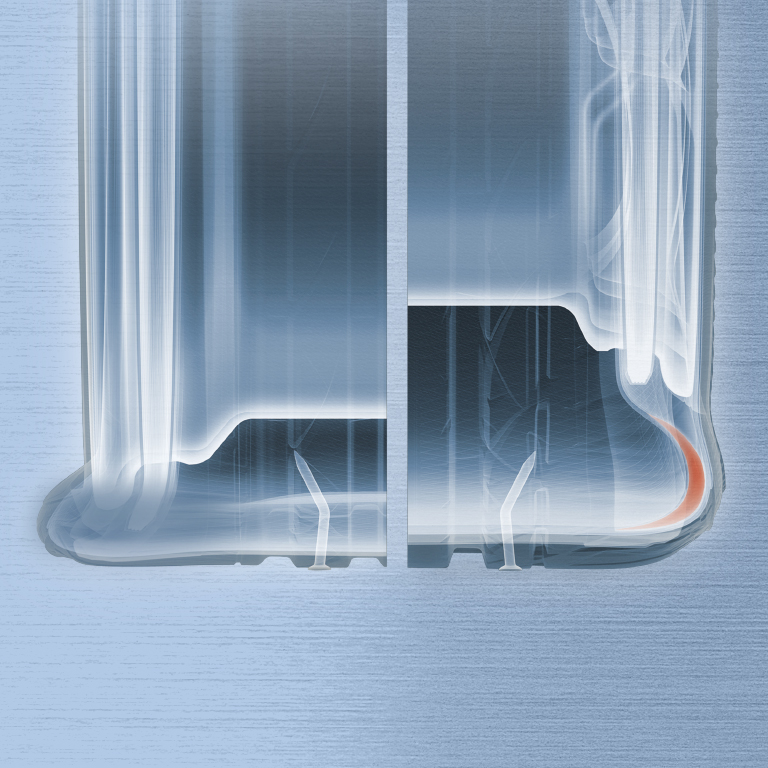

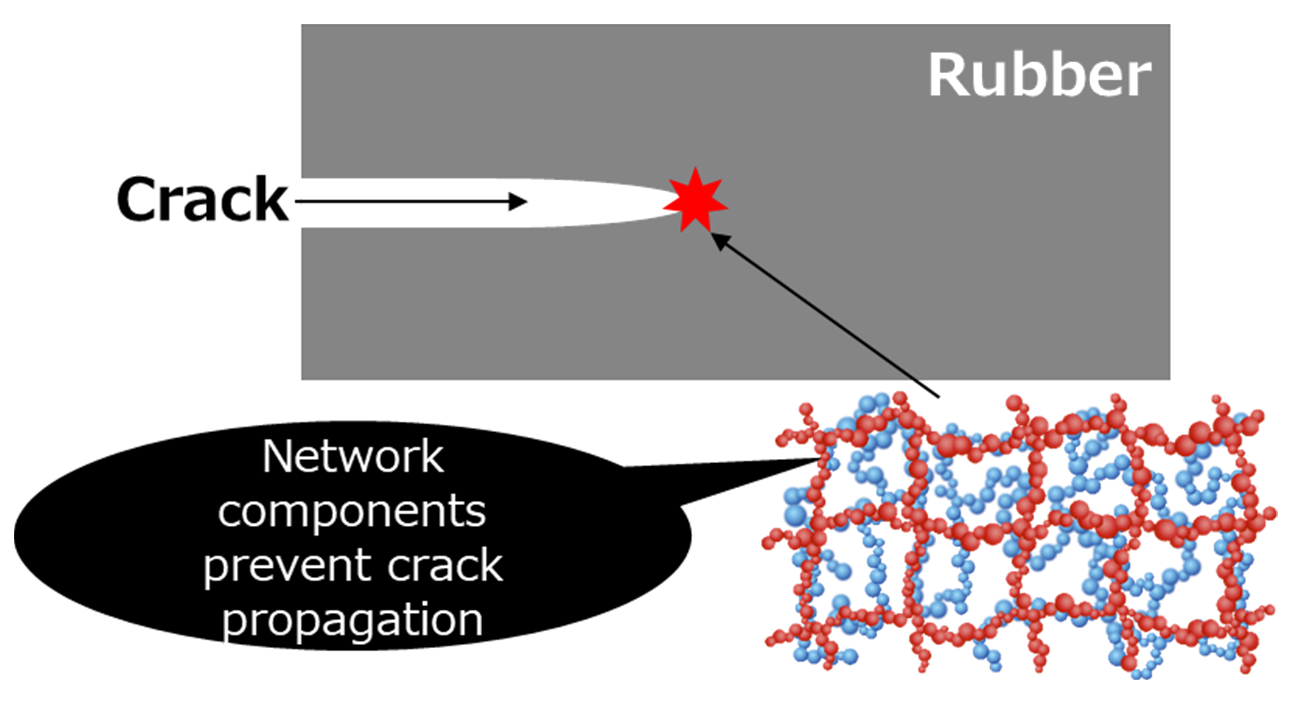

Durability Improving Mechanism

Through continued usage, tires can develop small flaws in sections of the rubber, contributing to wear or tire failure. The newly developed tightly linked network components help prevent the crack propagation of such initial flaws.

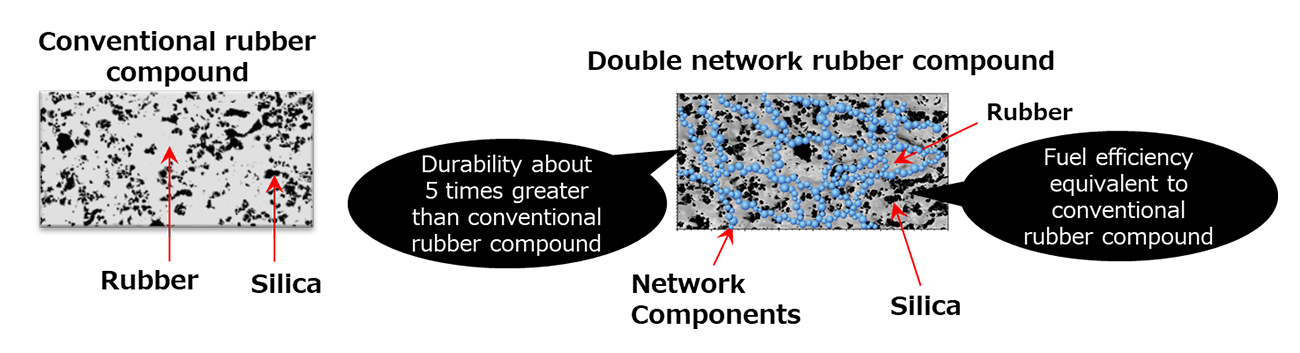

Double-Network Rubber Boasting Both High Fuel Efficiency and Durability

The combination of proprietarily developed double network structure with newly designed network components, sophisticated processing and compounding technologies makes it possible to maintain fuel efficiency equivalent to that of conventional rubber. At the same, the durability of double-network rubber is realizing durability that is five times greater than that of conventional rubber compounds since specially designed rigid network elements respond to strong forces that would normally destroy the rubber.

Tires Using Double-Network Rubber for ItoP Concept Car

Using double-network rubber, Bridgestone has developed a concept tire that features superior fuel efficiency and durability while also being lightweight. This concept tire is equipped on the ItoP concept car, contributing to an overall reduction in the weight of this vehicle. One of the successes of the ImPACT program, the ItoP concept car represents a vision for vehicles of the future and was created through a joint effort by various companies and organizations using durable, lightweight materials.

Looking ahead, Bridgestone will continue to promote open innovation while combining various technologies to make ongoing contributions to society’s mobility options.