Bridgestone’s Next-Generation “AirFree®” Tire that Does Not Need Air Filling

“Supporting the Mobility of Local Communities” with technologies focused on sustainability and safety with peace of mind

Bridgestone has positioned its next-generation AirFree tire, which does not need air filling, as an exploratory business in its Mid-Term Business Plan (2024–2026). Based on co-creation with external partners, we promote the exploration of business models that lead to creation of social and customer value.

Why Do Tires Need Air?

Conventional tires are filled with high-pressure air. Just as an inflated ball bounces well, air inside a tire enables it to support the weight of a vehicle and absorb shocks from the road, functioning like a spring. If tire pressure becomes inappropriate due to a puncture or other causes, it could hinder safe driving. Maintaining proper tire pressure is extremely important.

What is the Next-Generation “AirFree” Tire?

“AirFree” is Bridgestone’s next-generation tire that does not need air filling.

Instead of air filling, AirFree uses recyclable spoke-shaped thermoplastic resin to support loads. It prevents failures caused by punctures, contributing to improving resource productivity and maintenance efficiency to ensure non-stop mobility. Furthermore, the spokes are designed with “Empowering Blue,” a color to maximize visibility at twilight, empowering mobility of local communities with safety and peace of mind. In addition, “AirFree” contributes to sustainability through retreading and recycling.

“Empowering Blue” for enhanced visibility for safety with peace of mind

“AirFree” adopts blue spokes that ensure high visibility in all lighting conditions from daytime to dusk, contributing to safety with peace of mind. We call this blue color “Empowering Blue,” as it empowers and supports safe mobility with peace of mind in local communities.

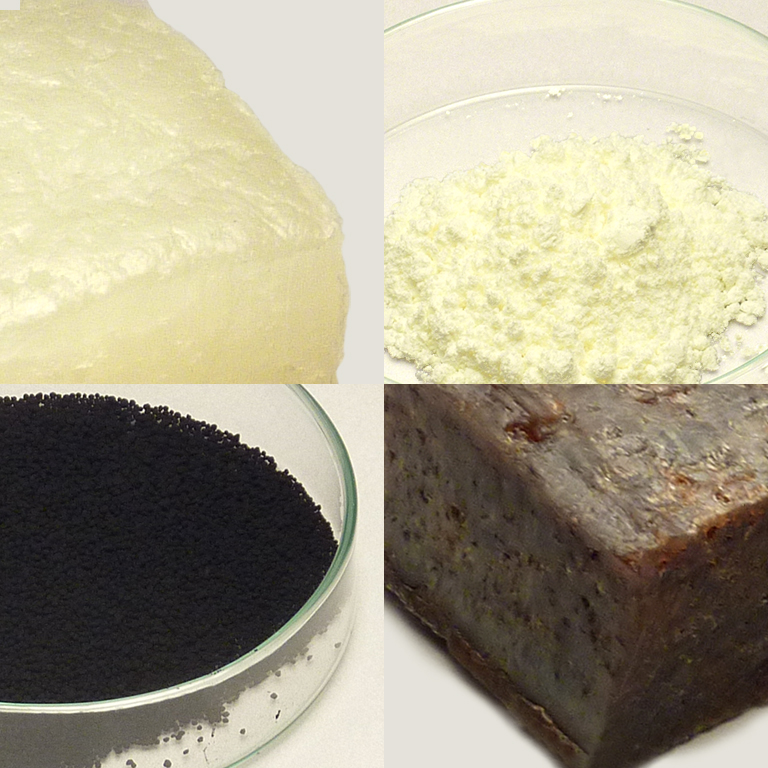

Sustainability: Use of Recyclable Resources and Retread

Not only can the rubber part that makes contact with the road be retreaded, but the uniquely developed spoke-shaped thermoplastic resin can also be recycled. These features contribute to efficient resource utilization and the realization of a circular economy.

-

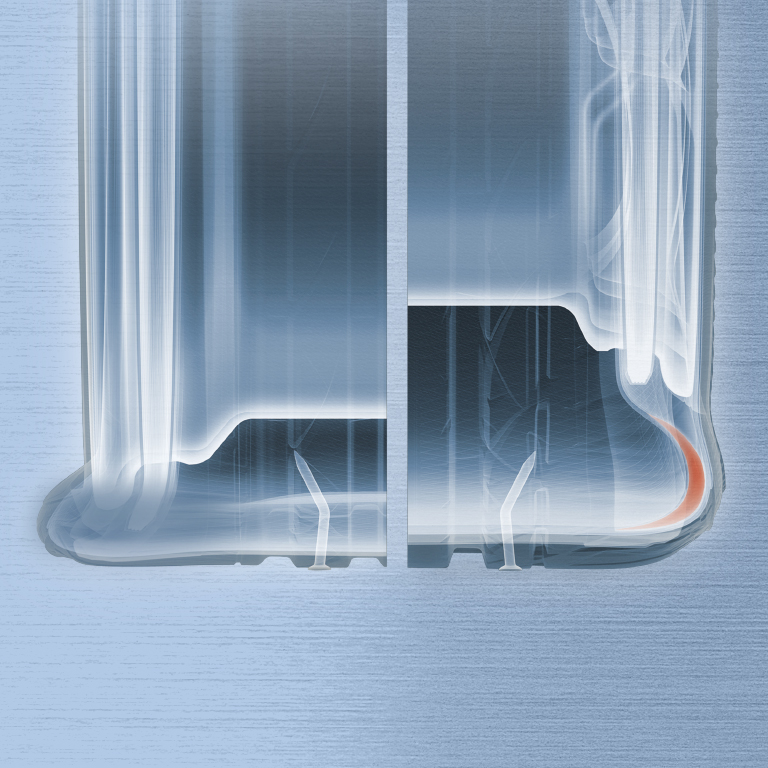

Simple structure for easy retreading and recycling

-

The spoke portion can be shredded into chips, melted, and remolded for recycling.

The Evolution and History of “AirFree”

Since 2008, we have been advancing our unique development of “AirFree” concept. With sustainability at its core, we have evolved our technology leveraging Bridgestone’s strengths in technology for “mastering rubber” and “mastering road contact”. “AirFree” has supported changes in social needs and the evolution of mobility, amplifying the value it delivers.

First Generation (2008–2012):

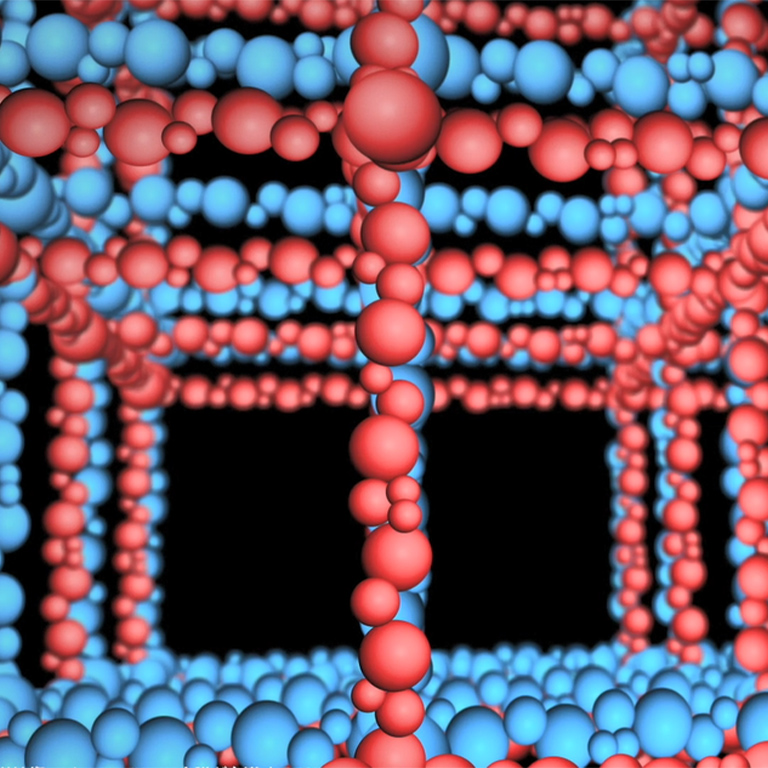

The first generation tackled the challenge of supporting loads with safety and peace of mind without air and ensuring recyclability. As a result, the load-bearing function typically provided by air in conventional tires was achieved by combining hard, robust materials and structures.

-

First Generation

Second Generation (2013–2022):

In the second generation, as mobility diversified, we not only focused on supporting loads with safety and peace of mind and recyclability, but also challenged ourselves to enhance ride comfort. By expanding the use of digital technologies and leveraging knowledge from conventional pneumatic tires, the structure evolved to disperse strain, meeting a variety of mobility needs.

-

Second Generation

Third Generation (2023–):

The third generation features advanced simulation technology and structural design for various usage environments, evolving into a structure that uses strong yet flexible materials and controls strain appropriately. In addition to conventional product functions, “AirFree” now aims to provide social value. With the mission of “supporting the mobility of local communities” by technologies focusing on sustainability and safety with peace of mind

, we have started public road demonstration experiments toward social implementation.

-

Third Generation

-

Shape optimization using AI-driven automated learning

From Concept to “AirFree” Towards Social Implementation

After overcoming various challenges, we began demonstration experiments on public roads in Kodaira City, Tokyo from March 2024. Looking toward the future, we are taking on the challenge of solving issues in local communities facing challenges such as an aging population, rural depopulation, and labor shortages, by adopting Green Slow Mobility as a key regional transportation solution. We will accelerate collaboration with various local governments to advance commercialization and technological development toward the creation of new value with “AirFree”.

Also by maximizing the non-pneumatic feature of “AirFree”, we aim to achieve even greater safety and peace of mind in combination with autonomous driving, where tire reliability becomes increasingly important.

Expanding Our Mission—From Local Communities to Space

The “AirFree” technology is also being utilized in tires for lunar rovers. Bridgestone, which has supported the evolution of any kinds of mobility on Earth by understanding roads around the world, is now gaining knowledge of “roads in space” and aiming to contribute to the advancement of humanity by supporting the evolution of space mobility. By expanding from Earth to space and the lunar surface, we plan to apply the technologies refined under the extreme conditions of the Moon to tires used here on Earth, thereby creating new value for society.