Looking Forward to 2050Bridgestone Announces Future Tire Technologies that Contribute to a Sustainable SocietyThe Goal is to Develop Tires with 100% Sustainable Materials

Tokyo, Japan (May 23, 2012) - Bridgestone Corporation today in Singapore announced the development of new tire technologies that will contribute to the realization of a sustainable society. These technologies, announced at the World Rubber Summit*1 2012 by Bridgestone Chairman of the Board, Shoshi Arakawa, are aimed at developing world-class tires made from 100% sustainable materials*2.

The transportation sector has a significant impact on the environment, particularly in terms of resource usage and CO2 emissions. As the world's largest tire and rubber manufacturer, the Bridgestone Group realizes that it has the potential to significantly lessen it impact on the environment. At the same time, the Group has defined its role as responding to the needs of customers around the world by reliably providing high-quality products that are technologically- advanced.

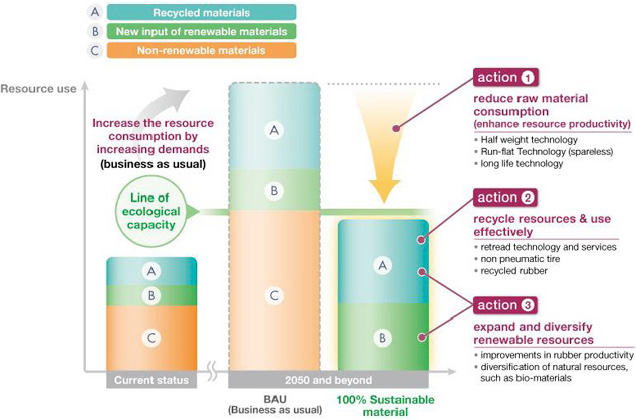

To fulfill its mission, the Group has established long-term environmental goals (see 1. below) to guide its pursuit of a sustainable society. The Group has placed a high importance on promoting the usage of 100% sustainable materials. To achieve this goal, Bridgestone will need fully leverage its technical capabilities and diversify and expand the range of renewable resources it uses in the production of tires and other rubber products. To accomplish this, the Group is diversifying the regions in which it produces natural rubber and expanding the range of reinforced plant fibers it uses. Furthermore, in order to replace fossil resources with renewable materials, the Group is working to develop synthetic rubber, carbon black, and rubber compounding agents that can be created from biomass materials. Looking forward to 2050, the Group will continue to advance the development of these technologies and will report on the progress of these initiatives as appropriate.

The Bridgestone Group is developing a number of technologies that can be applied throughout the value chain, from raw materials to finished products. One goal of these initiatives is to achieve the usage of 100% sustainable materials by leveraging 3R*3 technologies that diversify resources used and utilize renewable resources as well as retread technologies. In addition, the Group is pursuing the development of future tire technologies, such as those that reduce CO2 emissions through improved fuel efficiency. By creating ideal tires using these technologies, the Bridgestone Group will contribute to the realization of a sustainable society.

*1 World Rubber Summit (held from May 22 to 24 in 2012), sponsored by the International Rubber Study Group (IRSG), is the world's only global summit for rubber specialists. Participants include producers and consumers of natural and synthetic rubber from around the world, and the summit thus serves as an opportunity to discuss trends in the rubber industry and issues that will shape the future of rubber production from a global perspective.

*2 The term “sustainable materials” as used by Bridgestone is based on the Company's definition of materials that are not expected to be depleted should be continued, as opposed to fossil resources and other finite resources.

*3 The 3Rs are reduce, reuse, and recycle.

Details are as follows.

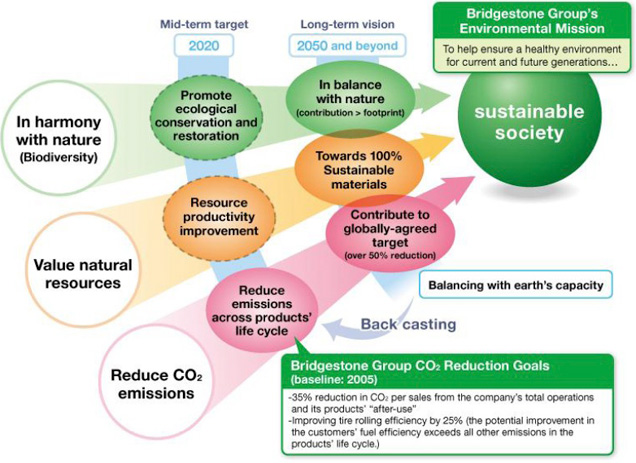

1. Bridgestone's Long-Term Environmental Goals

- Towards 100% sustainable materials: Focus on achieving the goal by leveraging the Group's technological and developmental capabilities

- Contribute to the globally-agreed target (for CO2 emissions reduction): Initiatives are already in place and producing results

- In balance with nature: Progression toward achieving the two goals above will also allow progress to be made toward achieving this goal

2. Specific Initiatives Moving Towards 100% Sustainable Materials

(1) Initiatives to Expand the Range of Renewable Materials Used

A. Diversifying the regions in which natural rubber is produced

In addition to producing natural rubber in tropical regions, the Group has also developed technologies that allow natural rubber to be produced from plants grown in arid and temperate regions. Using these technologies, the Group aims to alleviate the overconcentration of natural rubber production in certain areas. The main two plants the Group is currently researching are the Guayule and the Russian Dandelion.

Guayule

Russian Dandelion

B. Diversifying and expanding the range of reinforced plant fibers

The reinforced fibers currently used in tires include petroleum fibers, such as polyester and nylon, and plant fibers, like rayon. However, the Group has begun working to realize the practical application of new cellulose*1 fibers, which will significantly increase the ability for plant fibers to be supplied.

New cellulose fiber

*1 Celluose is a primary component in the cell walls and fibers of plants. Approximately 1/3 of all plant matter is cellulose, and it is the world's most common carbohydrate.

(2) Initiatives to Replace Fossil Resources with Renewable Resources

A. Developing synthetic rubber created from biomass materials

The Group has developed a technology that allows synthetic rubber to be produced using intermediate materials created from biomass materials. Utilizing the Group's material synthesizing technologies, the Group aims to turn these materials into renewable resources. One example of the success of this initiative would be the synthetic rubber that the Group has successfully created from butadiene*2 produced from bioethanol.

*2 Butadiene is the intermediate material most commonly used in synthetic rubber (butadiene rubber, styrene-butadiene rubber, etc.).

Bio-butadiene rubber

B. Developing carbon black created from biomass materials

The Group has developed a technology that allows carbon black to be retrieved from intermediate materials created from biomass materials. Utilizing the Group's material synthesizing technologies, we aim to turn these materials into renewable resources. One example of the success of this initiative would be the carbon black that the Group has created from vegetable fats and oils.

C. Developing new rubber materials created from biomass materials

The most common compounds that can be retrieved from biomass include bioethanol extracted from sugars, fatty acids*3 taken from vegetable fats and oils, cellulose and lignin*4 taken from wood, and other compounds consisting primarily of carbon, hydrogen, and oxygen. The Group is currently working to develop new highly-functional rubber materials utilizing this diverse range of materials.

- *3 Fatty acids used are taken for the fats and oils extracted from palm oil.

- *4 In addition to cellulose, lignin is also a common compound found in wood.

About Bridgestone Corporation:

Bridgestone Corporation, headquartered in Tokyo, is the world's largest tire and rubber company. In addition to tires for use in a wide variety of applications, it also manufactures a broad range of diversified products, which include industrial rubber and chemical products and sporting goods. Its products are sold in over 150 nations and territories around the world.

Bridgestone Corporation, headquartered in Tokyo, is the world's largest tire and rubber company. In addition to tires for use in a wide variety of applications, it also manufactures a broad range of diversified products, which include industrial rubber and chemical products and sporting goods. Its products are sold in over 150 nations and territories around the world.