Bridgestone Establishes ”Bridgestone Bandag Retread Center“ in Thailand-New operation signals accelerating development of retread and solutions business-

Tokyo (Feb. 25, 2010) - Bridgestone Corporation today announced that its subsidiary in Thailand, Thai Bridgestone Co., Ltd., today hosted an opening ceremony for its newly established “Bridgestone Bandag Retread Center” (BBRC).

BBRC will contribute to the development of the retread and solutions business in Asia in three ways:

1. Produce retread tires (*1)

The BBRC began the production of retread tires using the Bandag process (*2) on February 1, 2010.

2. Accelerate development of the retread and solutions business

Targeting truck and bus tire customers, BBRC will provide solutions-based business offerings using the Bandag retread manufacturing process. The BBRC retread and solutions business contributes to effective environmental business management and the reduction of total tire-related costs of transportation fleets and other customers by providing a complete package of new tires, retread tires, and tire maintenance services.

3. Conduct training for retread and solutions business

BBRC will conduct training for retread shop technicians in both BBRC's company owned and franchise locations. The training will include production of retread tires using the Bandag manufacturing process, and instruction in the BBRC retread and solutions business method.

The BBRC facility features a state-of-the-art retread shop facility that maximizes worker productivity and comfort. Emphasizing the efficiency and economy of the Bandag manufacturing process, BBRC has plans to expand its network of retread franchises and promote its retread and solutions business.

The Bridgestone Group anticipates that the retread and solutions business will significantly grow in Asia. To prepare for this growth, the Bridgestone Group is constructing a retread materials plant in Thailand. Production at the facility is expected to begin in November of this year.

An outline of the Bridgestone Bandag Retread Center is as follows.

| Location | : Nong Khae, Thailand (Facility is located inside the premises of the Nong Khae Plant owned by Thai Bridgestone Co., Ltd.) |

|---|---|

| Facility area | : 3,444m² |

| Facility details | : retread tire production line, panel display room, training room, etc. |

| Personnel | : staff for manufacturing retread tires: 4; managers: 2; plant director: 1 |

| Production capacity of retread tires | : 44 units per day |

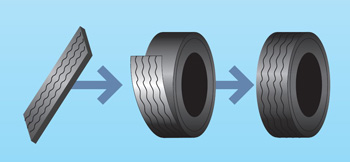

Retread tire manufacturing process

Opening ceremony

| *1. | Tires are retreaded by removing the worn tread (the part of the tire that touches the road) and then adding new tread rubber and vulcanizing it so that the tire can be reused. Compared to new tires, retread tires can make a major environmental contribution in three ways. | ||||||

|---|---|---|---|---|---|---|---|

|

|||||||

| *2. | The Bandag retread process uses pre-vulcanized tread rubber, which is applied to the tire casing and then vulcanized. This manufacturing process is also called the precure method. Reference: Image of the retread manufacturing process using Bandag method |

||||||

About Bridgestone Corporation:

Bridgestone Corporation, headquartered in Tokyo, is the world's largest tire and rubber company. In addition to tires for use in a wide variety of applications, it also manufactures a broad range of diversified products, which include industrial rubber and chemical products and sporting goods. Its products are sold in over 150 nations and territories around the world.

Bridgestone Corporation, headquartered in Tokyo, is the world's largest tire and rubber company. In addition to tires for use in a wide variety of applications, it also manufactures a broad range of diversified products, which include industrial rubber and chemical products and sporting goods. Its products are sold in over 150 nations and territories around the world.